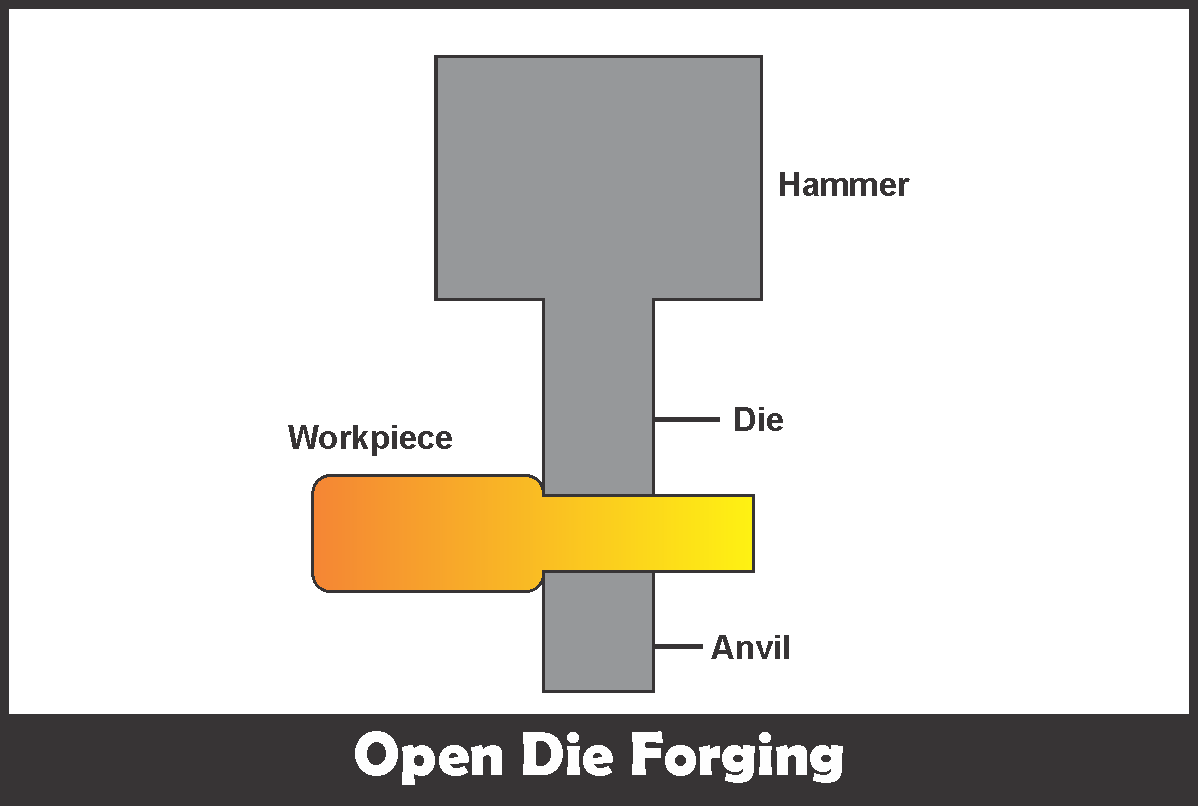

Open Die Forging is forming the metal piece using multiple dies that are not completely enclosed by the material. You can visit macrodynepress.com/hydraulic-presses/forging-presses/ to know about the open die forging press.

Image Source: Google

The material is modified when it is formed by the tools that "hammer" and "stamp" to the metal with various moves until the desired form is created.

Open forging products typically require a second grinding and refining in order to attain the precision required by final specifications.

Forging with open dies is commonly employed for products that are in small quantities that are easy to make rather than complicated products, such as discs rings and sleeves, cylinders, and shafts.

The shapes of your choice can be created using an open forging. The strength of grain structures is improved during deformation because of the continual working on the billet of steel.

Another advantage of open die forging can be that resistance to fatigue and the durability of the product is enhanced. In addition, voids can be reduced significantly following the open-die forging.

Open die forging is also called free forging. For open die forging the billet is positioned between several dies that do not cover the metal completely.

For the Open die forging process, a rough or precise machine is usually required following the open die process because the imprecise dimensions can be achieved by using hammers.

This is why an open forging method is appropriate for large pieces of hundreds of tons. In general, the items produced by the forging process comprise forged long shafts forging rollers, and forged Cylinders, which are typically employed in aerospace and railway.